Articles

Markings and Standards for Roller Skate Bearings: Differences and Purpose

Types of markings, their significance, and how to correctly choose roller skate bearings.

Bearings are the heart of roller skates, regardless of the type of rollers being discussed. It doesn’t matter what type of rollers you’re talking about.

The bearing is what makes the wheels rotate, enabling the rollers to achieve the desired speed. The quality of bearings directly impacts the performance of rollers in competitions and marathons and also influences the comfort of recreational skating.

This comprehensive guide will not only help you understand the differences but also make it easy to determine the type of component that is suitable for your skating style and skill level.

Bearing Standards (Markings)

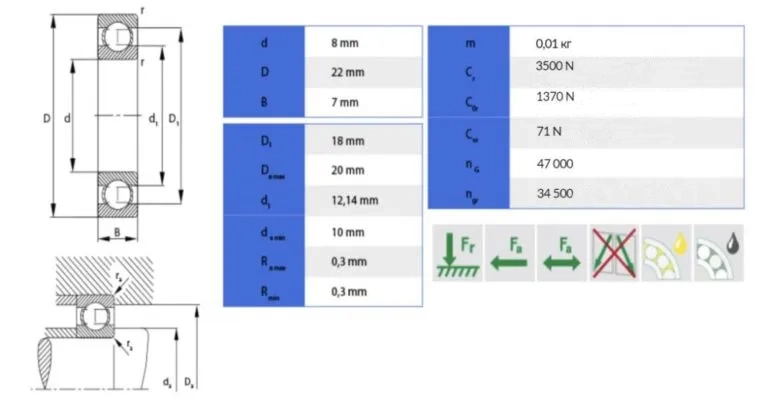

All bearings are divided into 2 standards (markings): 608 and 688. They are also referred to as sizes.

The 608 standard is based on the standardization of the manufacturing process: the number 60 denotes the product series, and the digit 8 represents the internal diameter of the bearing. Classic roller skates and quad rollers are typically equipped with 608 standard bearings, which are easy to maintain and allow for sustained high speeds during skating.

- The 688 standard has the same external and internal diameter of 8 mm as the 608 standard bearings, but they are thinner, reducing their weight by 2.5 times.

Bearings of the 688 standard also accelerate well and maintain speed, but they are more sensitive to dirt, dust, and water, requiring more careful maintenance.

Bearings Markings – ABEC

In the production of roller skates (as well as skateboards and scooters), bearings are typically marked with the designation “ABEC” followed by an odd number ranging from 1 to 9.

The abbreviation ABEC stands for Annular Bearing Engineering Council, and the number indicates the precision tolerance in manufacturing. The lower the number, the lower the tolerance (not speed!), and consequently, the lower the cost of the component.

How do the markings (classes) differ? Assessing the speed of a bearing based on its class is a common misconception among buyers. Many believe that a higher number in the marking means faster roller performance. However, this is not the case.

The marking determines how precisely the bearing is manufactured. A higher number implies a more precise and finely crafted component.

The class will impact the roll duration (how long the wheels spin without an additional push) and durability but not speed. Additionally, the marking helps determine which style of skating the component is suitable for.

What influences speed? We’ve established that the number in the marking is not indicative of speed. ABEC 9 bearings, for example, may not be the fastest by default but can provide a longer rolling momentum.

Factors that can influence speed include:

- Quality and consistency of the lubricant:

- A more viscous lubricant can slow down the rotation speed but increases the component’s lifespan.

- Conversely, a liquid lubricant allows for better acceleration initially but evaporates quickly, requiring frequent maintenance. This type of lubricant is not practical for fitness rollerblades.

- Quality and frequency of maintenance:

- Bearings of any marking (assuming no defects) will perform well initially after purchase. However, depending on usage and conditions, their performance may gradually decline.

Load and the duration of skating will necessitate lubricant replenishment, and inevitable exposure to dust, sand, and dirt will require timely cleaning and possibly component replacement.

Differences in ABEC Markings

As mentioned earlier, markings can be used to select components based on skating style. It’s also worth explaining the purpose of other bearing models from the popular manufacturer Powerslide, which often raises questions.

The most popular ABEC markings are ABEC 1, ABEC 3, ABEC 5, ABEC 7, and ABEC 9:

- ABEC 1 and ABEC 3:

- Lower precision class but higher resistance to impact loads.

- Often installed in scooters, skateboards, and roller skates in the lower price range.

- ABEC 5:

- Widely used in children’s roller skates, fitness skates, Freestyle Slalom (FSK), and aggressive skating by many manufacturers.

- Offers an optimal balance between price and quality.

- ABEC 7, ABEC 9:

- Less resistant to impacts but better for handling prolonged loads.

- Primarily used in fitness rollerblades and speed skating models.

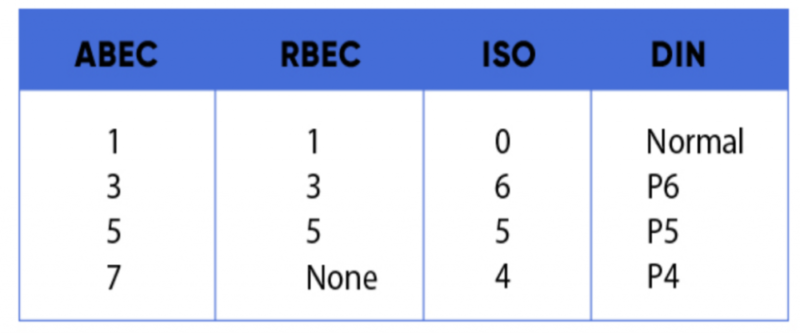

In addition to ABEC markings, there are other precision classes:

- RBEC (Roller Bearing Engineers Committee): Used by roller bearing manufacturers.

- ISO (International Organization for Standardization): International standardization organization.

- DIN (Deutsches Institut für Normung – German Institute for Standardization): German industrial standards.

The correspondence between these classes and ABEC is presented in the table below:

Other Types of Bearings from Wicked

The affiliated brand of Powerslide, Wicked, also produces bearings for roller skates, including types like Rustproof, Twincam ILQ9, Swiss, and others.

- Twincam ILQ7, ILQ9 Pro / Classic (Inline Line Quality)

Unlike ABEC, which is an established industrial standard, ILQ is not a standard defining bearing quality. It’s simply a designation used in Twincam bearings for marketing purposes.

Twincam bearings have a similar marking system to ABEC and offer good quality. The “Pro” bearings have a nylon cage and are typically used by speed skaters, while the “Classic” bearings have a steel cage, making them more suitable for urban and freestyle skating.

- Rustproof SUS bearings are suitable for skating, primarily for training sessions rather than competitions, in high humidity conditions. They are made from stainless steel, making them less susceptible to corrosion.

- Swiss bearings, a Swiss-manufactured model, do not carry any ABEC marking but stand out for their exceptionally high technical characteristics, quality, and speed. This is why many athletes in speed rollerblading prefer them.

According to the manufacturer’s comments, among the listed “unmarked” models, Swiss bearings are currently the fastest, followed by ILQ Pro, ILQ Classic, with Rustproof SUS bearings concluding the ranking.

Used Technologies and Materials

- Freespin Technology:

- Utilizes a special lubricant for smooth surface and fast rotation of Wicked ABEC 5, ABEC 7, and ABEC 9 bearings.

- Bearings with Freespin Technology consist of inner and outer rings, balls, and a raceway.

- Ceramic Bearings:

- Feature reduced friction, weight, and increased wear resistance.

- Most ceramic bearings are hybrid, with ceramic balls combined with steel outer and inner rings and raceway.

- Professional ceramic bearings are often made from silicon nitride (Si2N4), usually black, approximately 30% stronger than steel bearings, with a rounder and smoother shape that guarantees a significant reduction in friction.

- Stainless Steel:

- Combines chromium (at least 10.5%), carbon (no more than 1.2%), and nickel or other elements.

- Constantly covered with a protective layer of chromium oxide, providing corrosion resistance.

- Used primarily for skating in wet conditions, such as off-road rollerblading or speed races and marathons.

- Chrome Steel:

- Alloy of iron, carbon, and other elements obtained by immersing ordinary steel in a solution containing chromium.

- Chrome steel of the 52100 series is the most popular material for inner and outer rings, balls, and raceways in bearings.

- Special heat treatment and smooth surface ensure high fatigue resistance and quick, quiet rolling.

- Carbon Steel:

- High-tech material used in aviation, Formula-1 cars, and various sports equipment.

- Bearings made of carbon steel are not suitable for high-speed, high-load applications, and they are not corrosion-resistant.

- Often used in budget rollerblades for beginners due to their low cost.

- Carbon Hybrid Steel:

- Used in Wicked Carbon Pro bearings, combining chrome and carbon steel.

- Outer and inner rings with the raceway are made of stronger chrome steel, while balls are made of carbon steel.

- Provides smoother and more comfortable rolling compared to models made entirely of carbon steel.

Additional Insights:

- Stainless Steel: Resistant to corrosion, suitable for wet weather skating.

- Chrome Steel: Popular for its high fatigue resistance and smooth rolling.

- Carbon Steel: Low-cost material used in budget rollerblades but not suitable for high-speed or high-load applications.

- Carbon Hybrid Steel: Combines the strength of chrome steel with the smooth rolling of carbon steel.

Please let me know if you need more information or if there’s anything specific you’d like to explore.

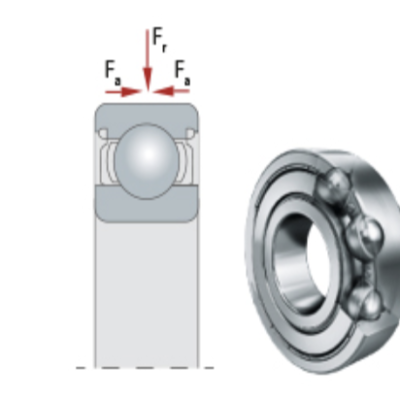

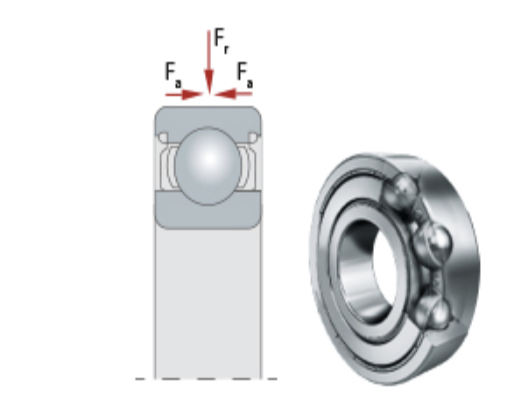

Seals in Bearings

Seals in bearings serve several crucial purposes:

- Uniform Distribution of Balls and Lubrication Around the Raceway:

- Seals ensure that the balls inside the bearing are evenly distributed and that lubrication is distributed uniformly along the raceway. This promotes smooth and efficient rolling of the bearing.

- Prevention of Wear Between Components:

- Seals act as protective barriers, preventing wear and tear between the various components of the bearing, such as balls and raceways. This contributes to the longevity and durability of the bearing.

- Achieving High Speeds:

- Seals play a key role in maintaining the stability of the bearing at high speeds. They prevent the ingress of contaminants and help retain lubrication, ensuring the bearing can operate efficiently even under demanding conditions.

To enhance precision and prevent additional wear, it is essential that the seal does not allow excessive radial displacement. Seals can be designed to be guided by either the balls or one of the rings to achieve this goal.

In summary, seals are critical components in bearings, contributing to their smooth operation, protection against wear, and the ability to achieve and maintain high speeds. If you have any specific questions or if there’s more you’d like to know, feel free to ask!

Types of Seals in Bearings:

Steel Seals:

-

- Made from various types of steel, typically having a crown shape and directed by the inner ring.

- Drawbacks include significant weight, risk of deformation of the protective coating under impacts, and susceptibility to corrosion in the case of carbon steel.

Plastic Seals:

-

- Composite products, often manufactured from reinforced nylon through injection molding. Materials such as polyethylene (PE) are used with stainless steel bearings, while polyether ether ketone (PEEK) is commonly employed with ceramic bearings.

- The plastic crown closes the ball guide. Unlike steel, plastic seals have higher sliding properties and induce sharp temperature fluctuations in the working torque. This allows for a 60% increase in maximum speed with low noise levels.

- Disadvantages associated with steel retainers are considered advantages for plastic ones.

ZZ (2Z) Seals:

-

- Bearings with this type of seal are covered on both sides by a non-removable seal that does not come into contact with metal. It is secured to the outer ring through a pressing method. The seal cannot be removed after factory assembly, allowing only basic maintenance such as cleaning the outer ring and wiping off moisture after riding in wet conditions.

- The abbreviation “Z” in the suffix denotes the presence of one protective shield, while “ZZ” (or “Z2”) signifies two.

- Commonly used in low-cost segment rollerblades.

These seal variations cater to different needs and are employed based on factors such as cost, maintenance requirements, and the intended use of the bearings. If you have any specific questions or need further clarification, feel free to ask!

ZZS / ZS:

- Removable Seal: ZZS/ZS bearings feature a detachable seal that does not come into contact with metal and is attached using a snap-on wire ring (C-ring). This technology prevents contact with the inner ring.

- Advantages of C-ring attachment: It avoids excess friction and heating, prevents lubricant leakage (in ZZS version), and requires less frequent maintenance.

- Drawbacks: Limited protection against dust and water ingress, especially in the ZZ version.

2RU / RU:

- Nitrile Rubber Seal: 2RU/RU seals are made of nitrile rubber (NBR) attached to a steel bushing. It is installed on the outer ring through a special groove. It can be removed, but caution is needed to avoid bending or cutting the edges.

- Thin Edge Design: The seal has a very thin edge that does not contact the inner ring, providing higher protection than ZZ and ZZS. Proper cleaning materials should be used as different lubricants and chemicals often react with rubber.

2RS / RS:

- Removable Molded Seal: 2RS/RS bearings feature a removable molded rubber seal (NBR) attached to the outer ring through a groove.

- Direct Contact with Inner Ring: Unlike metal shields, the rubber seal in these bearings comes into contact with the inner ring, enhancing protection against dirt and water ingress. However, this increases friction and reduces the ability to achieve high speeds.

Each type of seal has its advantages and drawbacks, catering to specific needs and usage scenarios. If you have further questions or need additional information, feel free to ask!

Labyrinth Seal:

- Material: The labyrinth seal, or screen, is also made of rubber (NBR) and completely fills the space between the inner and outer rings of the bearing.

- Connection to Inner Ring: The seal is connected to the inner ring through grooves, enhancing sealing and preventing the ingress and accumulation of dirt and moisture. It also reduces the frequency of maintenance without affecting the torque.

- Usage in Stainless Steel Bearings: This type of seal is commonly used in stainless steel bearings, suitable for wet weather conditions.

Closed and Semi-Closed Bearings:

- Closed Bearings: These bearings are equipped with seals on both sides.

- Semi-Closed Bearings: These bearings have a seal on only one side.

It’s crucial for the semi-closed bearing to have the open side facing the inner part of the wheel to protect against dirt and moisture.

Advantages of Semi-Closed Bearings:

- Lighter Weight: Semi-closed bearings are lighter in weight.

- Ease of Maintenance: They are easier to maintain.

Drawbacks:

- Not Fully Protected: Semi-closed bearings are not fully protected against dirt and water.

- Fast Lubricant Evaporation: There might be a faster evaporation of lubrication.

- More Frequent Maintenance: They may require more frequent maintenance.

These details help users understand the characteristics and considerations associated with labyrinth seals and closed/semi-closed bearings. If you have any more questions or need further clarification, feel free to ask!

Lubricants for Bearings:

Lubrication is essential for preventing friction, heat, and corrosion between the contact points of bearing elements (balls and the raceway). The choice of lubricating material significantly influences factors such as maximum speed, temperature rise, torque levels, noise, and the durability of the bearing.

Types of Bearing Lubricants:

- Mineral or Synthetic Grease:

- Common Use: Often used in bearings designed for high-speed applications.

- Variety of Synthetic Oils: There is a wide variety of synthetic oils available in the market, and each professional speed skater may have their preferred type, contributing to the uniqueness of their bearing performance.

- Viscosity Differences: Mineral and synthetic greases can vary in viscosity. Lower viscosity makes the material more liquid, easier to apply, reduces friction, increases speed, but may require more frequent maintenance due to faster evaporation.

- Silicone Grease:

- Temperature Range: Possesses a broad temperature range and is less affected by viscosity changes when heated.

- Water Repellent: Good at repelling water.

- Application: Not commonly used for high-speed applications but is well-suited for rollerblading in wet conditions.

- Plastic Grease:

- Composition: A mixture of oils with a thickener that allows the material to remain inside the bearing for an extended period, reducing the need for frequent maintenance.

- Cautions: Excessive use can decrease bearing performance, leading to increased resistance. Adequate space within the bearing is necessary for heat dissipation between balls and the raceway.

- Teflon Additive:

- Function: Teflon is an additive used in grease to prevent corrosion and enhance the operational characteristics of standard plastic grease.

Choosing the right lubricant involves considering the specific requirements of the application, such as speed, temperature, and environmental conditions. Each type of lubricant has its advantages and limitations, and the choice depends on the desired performance characteristics and maintenance preferences. If you have any further questions or need additional details, feel free to ask!

Bearing Maintenance:

Regular maintenance of bearings is crucial for preserving their performance and longevity. The first signs indicating the need for a diagnostic check on bearings include unusual sounds or slow rotation. Here’s a step-by-step guide for bearing maintenance:

- Disassemble the Wheel and Extract the Bearing:

- Carefully take apart the wheel to access the bearing.

- Extract the bearing from its housing.

- Remove the Seal (if Possible) Using a Needle:

- If the bearing has a removable seal, carefully use a needle to lift and remove it.

- Place Components in a Small Container with a Mild Cleaning Solution:

- Place all components, including the bearing and removed seal, into a small container filled with a mild, non-aggressive cleaning solution.

- Gently Clean Each Component with a Brush:

- Use a small brush to delicately clean each component, ensuring that any accumulated dirt or debris is removed.

- Dry Cleaned Components on a Towel:

- After cleaning, lay out the components on a towel to air-dry completely.

- Apply Lubrication to the Bearing:

- Apply synthetic or the preferred type of lubrication to the bearing. Ensure an even coating to promote smooth operation.

- Reassemble the Bearing and Insert it into the Wheel:

- Reassemble the bearing components and insert the bearing back into the wheel.

Regular maintenance not only extends the life of the bearings but also contributes to optimal performance. The cleaning and lubrication process helps in eliminating debris and reducing friction, ensuring smooth and efficient rotation. If you have any more questions or need further clarification, feel free to ask!

You’re absolutely right; there isn’t a one-size-fits-all recommendation for the frequency of bearing maintenance. Each roller has its unique usage patterns and conditions. However, some general guidelines can help roller enthusiasts keep their bearings in good condition:

- Regular Inspection:

- Check your bearings regularly for any signs of wear, damage, or unusual sounds.

- Post-Rain Maintenance:

- After riding in wet conditions, make it a habit to wipe and dry the wheels thoroughly. This helps prevent rust and keeps the bearings functioning well.

- Listen for Warning Signs:

- Unusual noises during skating, such as grinding or clicking sounds, can be indications of bearing issues. If noticed, investigate and address promptly.

- Individual Usage Patterns:

- Adjust maintenance frequency based on personal usage patterns. Skaters who ride more frequently or in challenging conditions might need to perform maintenance more often.

- Professional Inspection:

- If there’s any doubt about the condition of the bearings or if issues persist, seek the assistance of a professional who can provide a more thorough inspection.

In essence, staying attentive to the performance of your roller bearings and addressing issues promptly is key. Developing a maintenance routine based on personal experience and the specific conditions in which you skate will contribute to the longevity and optimal functioning of your bearings. If you have any specific concerns or questions, feel free to ask!